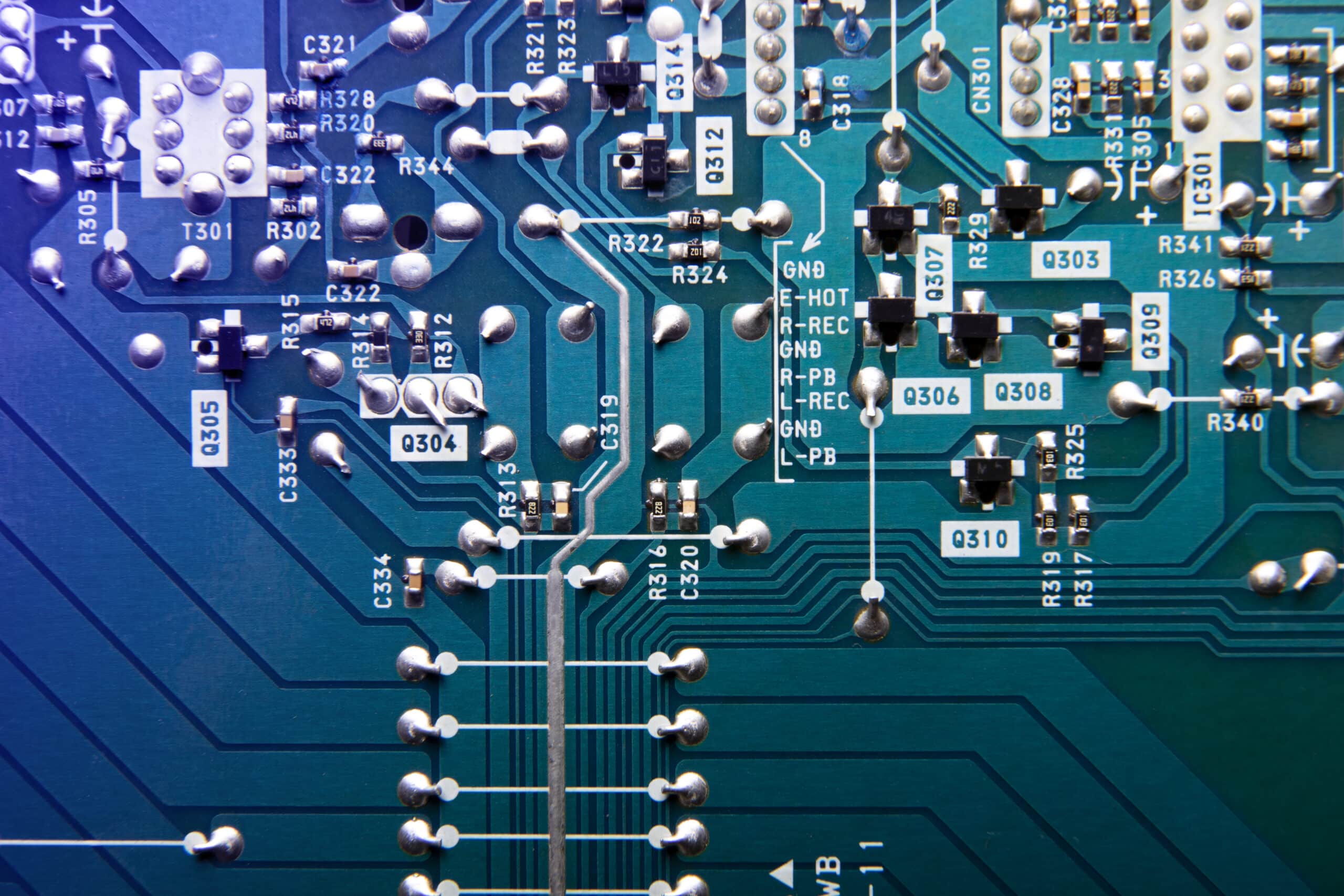

Choosing the right PCB material is an important step in creating high -quality and reliable electronic devices. In this blog post, we will explore the factors and considerations used to choose the best circuit board material while remembering the performance requirements and budget.

You will learn about various types of PCB materials, their unique nature, and how they can affect the success of your overall project.

Takeaways key

- Choosing the right PCB material is very important for optimal performance and endurance, and factors such as thermal management, signal integrity, costs, compatibility of manufacturing processes, and environmental problems must be considered.

- Effective thermal management prevents component failure and reducing efficiency problems by ensuring proper cooling during regular operations. Combining metal core materials or heat sinks can increase heat dissipation in PCB design.

- Signal integrity maintains clear communication between components in electronic devices by maintaining the waveforms from electrical signals that travel through the traces of the circuit board – without distortion or distortion. Material with a stable dielectric constant (DK) in the broad frequency range is recommended to demand applications such as wireless communication systems.

- Defining the previous application requirements helping to narrow the appropriate PCB material options to identify those who meet the needs of the project while optimizing the effectiveness of costs during production-by considering important considerations such as environmental impacts and maintaining high quality standards throughout the selection process.

Factors to consider when choosing PCB material

Choosing the right PCB material is very important to achieve optimal performance and durability for your circuit board. To make decisions based on information about the best material, several factors must be taken into account.

Thermal management refers to how efficient heat can be removed from the components mounted on the PCB board. For example, copper carries out heat well because of high thermal conductivity while other materials such as ceramics have lower heat transfer resistance per unit area per unit thickness.

Signal integrity helps maintain proper communication between components in electronic devices by ensuring that the signal remains stable and clear in all circuit boards even at higher frequencies or faster data speeds.

Another determining factor when choosing PCB material is cost efficiency; Using low -cost options may come with a reduction in quality and durability but may seem attractive especially for projects that are sensitive to the budget while choosing a high -class solution can significantly increase production costs negatively affect the overall cost negatively if it is not justified properly by improving product functionality or the benefits of increasing life from time to time.

Finally, environmental problems have grown more significantly from time to time because the company now faces regulatory pressure to choose environmentally friendly PCB materials.

Consideration when choosing PCB material

When choosing PCB material, consideration must be made for thermal management, signal integrity, costs, manufacturing process, and environmental problems.

Thermal management

Effective thermal management is an important aspect of the selection of PCB material, because it ensures optimal performance and long life of the printed circuit board, which depends on the quality of the printed circuit board material used by the printed circuit board manufacturer. Inadequate heat dissipation can cause component failure, reducing efficiency, or even thermal escape that can cause severe damage to the device. So, make sure you choose people who use good ingredients when choosing ingredients.

One common method for increasing heat dissipation in PCB design is to combine metal core materials or heat sinks that efficiently transfer excess heat from critical components.

In addition, choosing a substrate with an excellent thermal conductivity can ensure proper cooling during regular operations. For example, FR-4 lamination offers moderate thermal management capabilities but may not be enough for high power applications where more sophisticated materials such as PCB supported by aluminum are needed.

Signal integrity

Signal integrity is an important aspect of the selection of PCB material, because it directly affects the quality and efficiency of data transmission in electronic devices. Simply put, signal integrity refers to maintaining the shape of the wave or electrical signal shape that is traveling through the traces of the circuit board – without interference or distortion.

Dielectric Constant (DK) is one of the key parameters when evaluating the material on its impact on signal integrity. Different PCB material shows various levels of DK value; Lower values are generally more suitable for high -speed digital design where the minimum delay time is desired.

For example, FR-4 is widely used in most applications because of its low costs and availability but can show limitations in meeting the requirements of strict signal integrity at higher frequencies.

Cost

The cost of PCB fabrication is an important factor to consider when choosing the right material for your circuit board. Prices can vary depending on several factors, including the complexity of the design, the number of layers needed, and special materials.

It is important to remember that PCBs with more layers tend to be more expensive than those who have less layers. Also, special materials used for high frequency applications or hard environment can add additional costs.

However, choosing a cheaper material can affect the quality and reliability of the final product because they may not have the desired electrical properties such as endurance and thermal conductivity.

Making process

The manufacturing process is an important factor to consider when choosing the right PCB material. The choice of material must be suitable for the manufacturing process in question, whether it is through a hole or surface-mount (SMT) technology.

For example, FR-4 is a popular choice for SMT assembly because of its excellent drill and performance capabilities in a high temperature environment. On the other hand, Flex PCB requires different materials such as polyimide to handle bending stress without cracking or rupture.

Therefore, it is very important to consult with experienced producers who understand how different materials behave under certain conditions during assembly and use.

Environmental problems

The type of material used for PCB can have an impact on the environment, making it important to consider when making choices. Ingredients such as lead and toxic cadmium and can pose a risk if they are not removed properly.

In addition, some materials may require more energy or resources to be produced, which can increase their environment.

For example, some companies offer PCB materials made from natural fibers such as flax or traditional fiberglass cotton. These natural ingredients reduce carbon emissions during manufacturing while maintaining the performance of reliable circuits.

Some boards also use recycled plastic or other sustainable materials that should end up in a landfill.

PCB Material Selection Process

To choose the ideal PCB material, it is important to determine the requirements of your application, identify appropriate materials based on performance and budget considerations, evaluate these options as a whole, and verify that your choice meets the project needs – continue to read to find more about this important process.

Determine PCB Application Requirements

Before selecting PCB material, it is important to determine application requirements. This involves consideration of factors such as operating temperature range, signal frequency and voltage, size constraints, and environmental conditions.

In addition, for high frequency circuits that require maintenance of signal integrity and minimal attenuation loss in the transmission pathway, PCB material with low dielectric constants is recommended.

Conversely, when cost optimization is the main consideration for less demanding applications such as low -speed digital circuits or power supplies that operate at lower frequencies or voltages can use cheaper material options without sacrificing performance.

Identification of appropriate PCB material

To identify the appropriate PCB material, one must first determine the requirements of the circuit board application. Factors such as operating frequency, power dissipation, and environmental conditions play an important role in determining material selection.

After the application requirements are defined, engineers can identify potential PCB materials that suit their needs. General options include FR4 for standard applications and polyimide or ceramics for higher performance needs.

It is important to verify decisions made by testing the prototype produced using selected materials. This ensures that the overall performance meets expectations before moving forward with running production.

Evaluate the selected material

After you identify some of the appropriate PCB material options, it’s time to evaluate each thoroughly. This step involves a review of technical specifications and data tests for each potential material and compare them with the requirements of your application.

Consider factors such as thermal management capabilities, signal integrity, costs, and environmental problems when evaluating materials. In addition, applying the practice of DFM (design for manufacturers) during the evaluation process can help ensure that manufacturing challenges are minimized.

Verification of PCB Material Selection

After you identify and evaluate the suitable PCB material for your application, it is important to verify that the selected material meets your needs. This can be done by doing a test or simulation on a prototype PCB using the selected material.

It is also important to consider potential manufacturing problems that may arise when working with the selected PCB material, such as difficulty in drilling or soldering.

Conclusion

Choosing the right PCB material is very important for electronic projects. This has an impact on performance, reliability, and cost of all projects. When choosing PCB material, it is important to consider factors such as thermal management, signal integrity, manufacturing process and environmental problems.

The material selection process must involve defining specific requirements for the application and identify the appropriate material for the evaluation. In the end, verifying and agreeing to the material you choose will ensure quality results.

football News

Berita Olahraga

News

Berita Terkini

Berita Terbaru

Berita Teknologi

Seputar Teknologi

Drama Korea

Resep Masakan

Pendidikan

Berita Terbaru

Berita Terbaru

Berita Terbaru